INTRODUCTION:

Potable reuse refers to recycled water people can drink. The water produced through a potable water reuse treatment process is commonly referred to as purified water. Wastewater travels through sewers and pipelines to community wastewater treatment plants. There, it is either cleaned to a level where it is safe to return to the environment, cleaned further to be used for non-drinking applications, or sent to a water purification facility for additional cleaning to be used for drinking. Saltwater and stormwater can also be recycled for drinking.

Communities choose purified water for drinking water for many reasons, including:

During the past several decades, treated wastewater (also called reclaimed water) has been reused to accomplish two primary purposes:

(1) to create a new water supply and thereby reduce demands on limited traditional water supplies and

(2) to prevent ecological impacts that can occur when nutrient-rich effluent is discharged into sensitive environments.

Increasingly, the basic need for additional water supply is becoming the central motivator for water reuse. In addition to growing water demands, the further adoption of water reuse will be affected by a variety of issues, including water rights, environmental concerns, cost, and public acceptance.

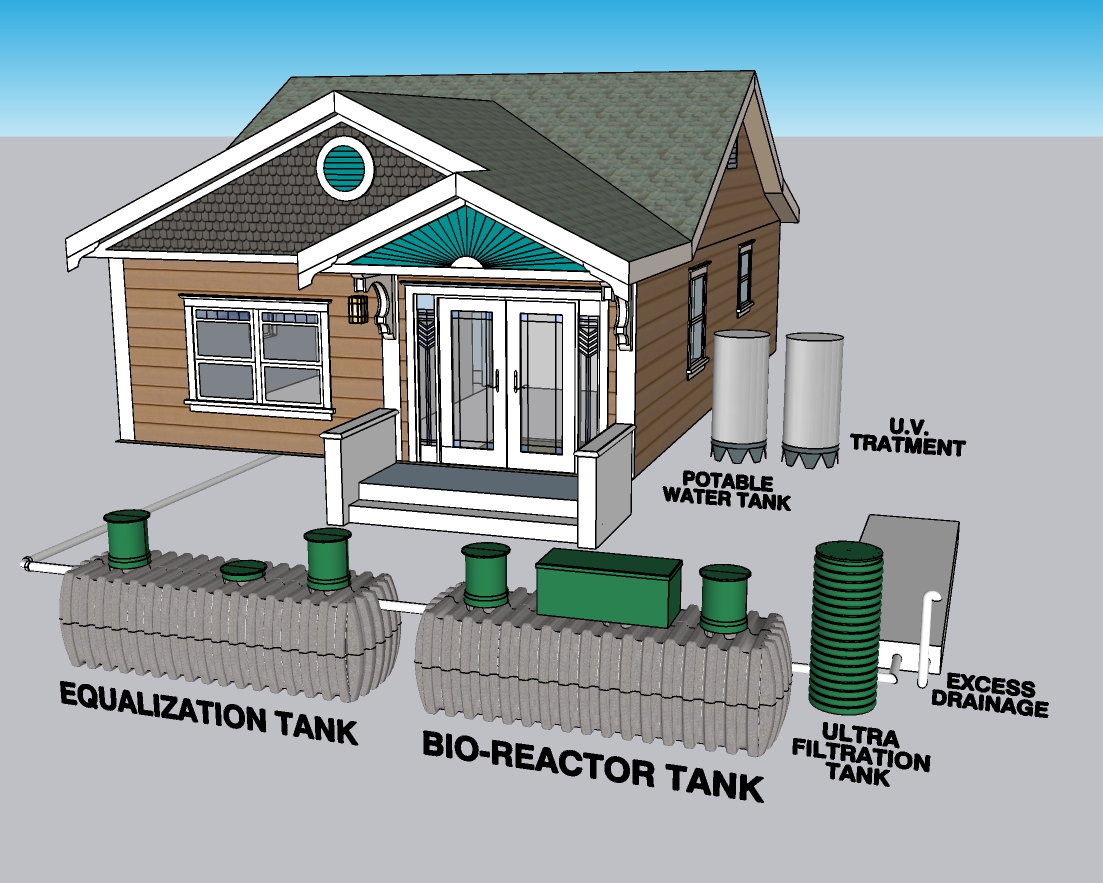

INTRODUCING THE NEXTGEN SEPTIC DIRECT POTABLE REUSE (DPR) SYSTEM

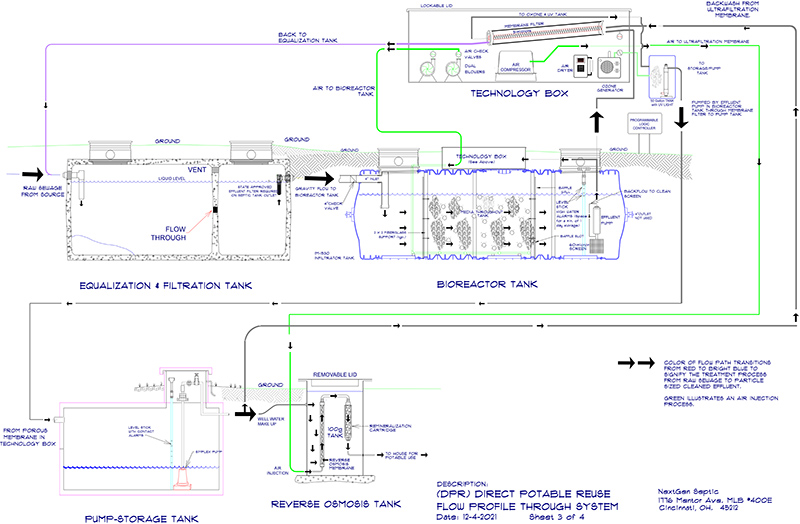

The NextGen Septic DPR process is designed to treat the wastewater from a single-family house (maximum flow rate of 1,000 gallons per day) using a three-step treatment system. The first step consists of a 1,730-gallon, standard, plastic septic tank, installed below ground, which has a single baffle. This tank serves as the Equalization and Filtration Tank. Wastewater with solids from the house flows by gravity into this tank, wherein the solids are allowed to settle down and the clear liquid, overflowing the baffle, flows into the second compartment, wherein there is a self-cleaning filter (50 microns), which is equipped with a submersible pump. This pump flows some of the filtered water to the rotating nozzles, located inside the screen, which continuously cleans the screen, while the remaining filtered water flows into a second, identical, 1,730-gallon septic tank, also installed below ground.

This second Bioreactor tank represents the second treatment step, in which the water is aerated using a blower and porous tubes, installed at the bottom of the tank. There is moving biomedia, consisting of a spherical plastic mesh (2 inches in diameter) in which a 2-inch cubic piece of open cell foam is enclosed inside the mesh. These balls of Biomesh Biomedia move around the tank, while it is being aerated. The plastic mesh protects the open-cell foam from being clogged by the suspended particles, while the open-cell foam inside the mesh provides a very high surface area for the active biofilms. A drawing of the moving Biomedia and the first and second septic tanks are attached in the following sheets.

Biomesh Biomedia balls consist of a spherical, plastic mesh enclosing a 2-inch cube of open-cell foam. The outside surface of the open-cell foam immobilizes aerobic biofilms, while the inside surface area of the foam, which has limited penetration of dissolved oxygen, supports anoxic biofilms. These anoxic biofilms convert nitrate/nitrites to nitrogen gas. The contaminants (BOD, ammonium, etc.) are treated in this Bioreactor Tank, which has a single baffle, that separates the tank into two compartments. Water from the Bioreactor compartment flows into the smaller second compartment, which has a self- cleaning filter (50 microns screen size) and a submersible pump. This self-cleaning pump is identical to the self-cleaning filter in the first septic tank. Filtered water from the self- cleaning filter in the second septic tank is pumped to a 5-micron screen size, stainless steel membrane, which is located inside a Technology Box, shown below. This Technology Box is usually installed on top of the second Bioreactor Tank, between the two risers, such that the cover of this box and the riser covers of the second Bioreactor Tank are above ground. This allows easy access to the components inside the Technology Box, for maintenance purposes.

Water that passes through the 5-micron membrane flows into a separate 100-gallon tank, while the unfiltered water, which does not cross the stainless-steel membrane is recycled back to the first septic tank. The technology box also houses an air blower and a stand-by blower. In addition, the Programmable Logic Controller (PLC) and an air compressor are also installed inside this box. Filtered water from the stainless-steel membrane flows into a 100-gallon tank, shown below, which houses a submerged Ultrafiltration Membrane, with an average membrane pore size of 0.03 microns. There is a submerged pump in this 100- gallon tank, which pumps the water back into the stainless-steel membrane to periodically back flush the solids off the stainless-steel membrane into the first septic tank. A reversible pump pulls water from the Ultrafiltration Membrane in the 100-gallon tank and stores it in a 20-gallon tank. Periodically, this pump reverses to push water from this 20-gallon tank to back flush the Ultrafiltration membrane. Water from the 20-gallon tank is pumped through a venturi in which ozone, created from dried, ambient air, is mixed to disinfect the water.

Ozone is made from ambient air, from the air compressor, which is dried in a regenerable air dryer and then through a solid-state ozone generator, which generates 3-4 volume% ozone from the oxygen in the dried ambient airflow. Ozone is a very strong disinfectant. Treated water is then pumped through a Reverse Osmosis membrane, which is also inside the 100- gallon tank, although not shown to maintain clarity. Water that passes through the Reverse Osmosis (RO) membrane flows into an 80-gallon bladder tank, which is maintained at 70 psi air pressure. The water from the RO membrane is pumped to a higher pressure than 70 psi to fill the bladder tank. Water from this bladder tank is then supplied to the house for potable water consumption. The DPR treatment process is controlled by the Programmable Logic Controller (PLC), which allows the membranes to automatically back flush to keep the membrane clean from any debris and biofilms. It also monitors the quality of the water going into the bladder tank by measuring its turbidity in real-time. If there is any detectable turbidity measured going into the bladder tank, the PLC closes the valve on this line, thereby preventing any contamination of the water in the bladder tank.

COPYRIGHT © 2020. NEXTGEN SEPTICS. ALL RIGHTS RESERVED.