FACULTATIVE MEMBRANE BIOREACTOR SYSTEM

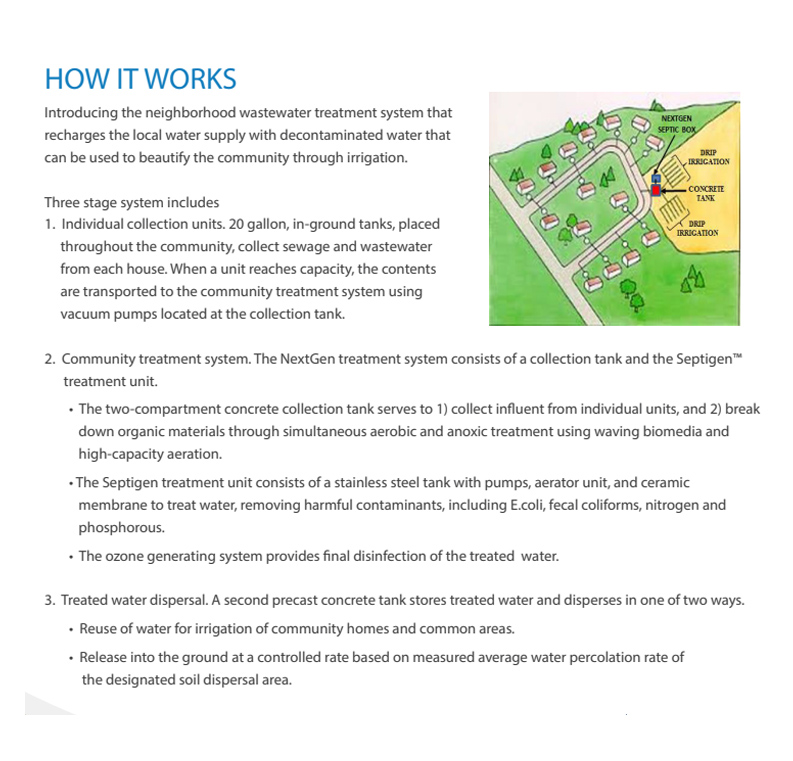

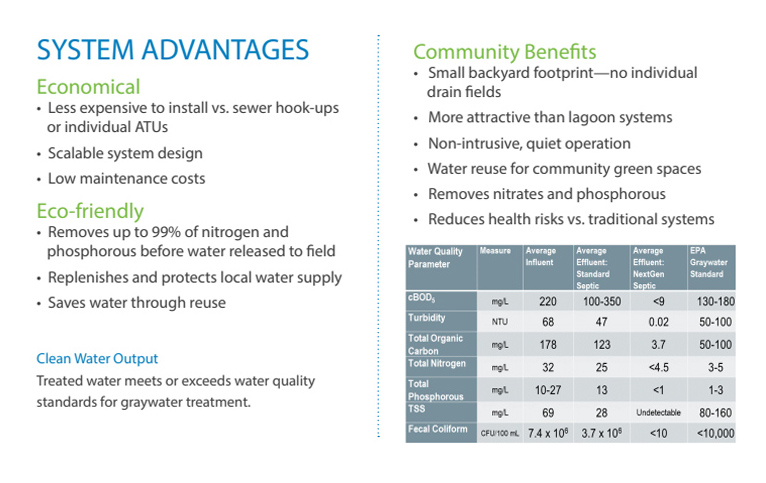

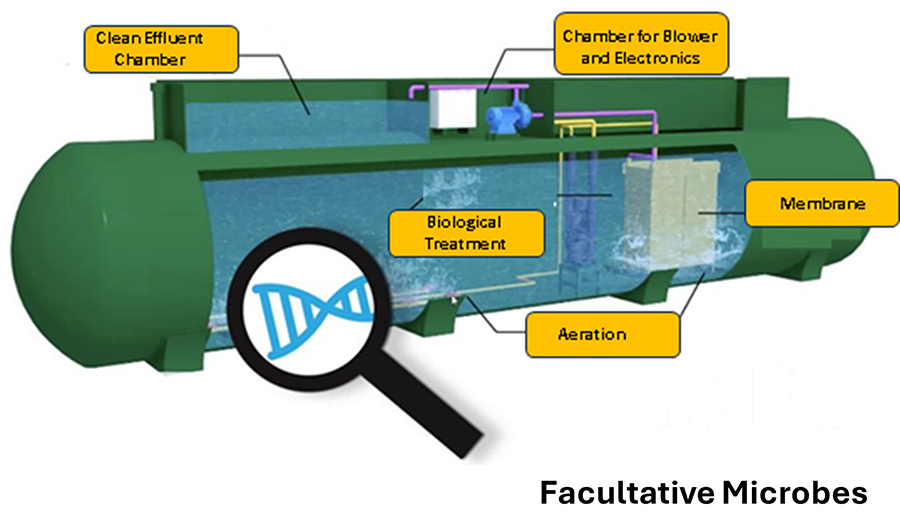

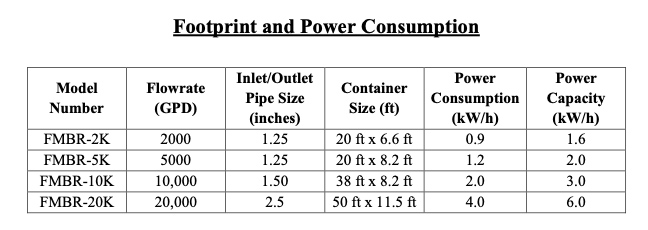

NextGen Septic is marketing the Facultative Membrane Bioreactor (FMBR) system for communities with wastewater flowrates greater than 1,000 gallons per day up to 100,000 gallons per day. The facultative membrane bioreactor (FMBR) is a low-energy membrane biological wastewater treatment process that removes carbon, nitrogen, and phosphorus in a single reactor under a low DO (dissolved oxygen) facultative environment. It encourages natural microbial competition, maximizes the activity of the mixed biomass consortium, saves energy, and meets nutrient discharge limits with simple controls.

The key to the core technology of the FMBR is that it can operate under a low oxygen condition to accomplish biological treatment while preventing the membrane from biofouling. Under a facultative environment, FMBR has a low sludge yield rate, just like most anaerobic systems. Still, it is not sensitive to the impact of its toxicity and pH change treatment performance. It replaces the complex reactors in a series of traditional BNR processes with a single reactor. FMBR is a pre-designed compact engineering system. It can be installed on-site without a dewatering system and the investment in a long sewer pipeline.

The first FMBR full-scale demonstration project in North America was at the Plymouth Municipal Airport (PMA). The existing PMA plant was an SBR system with an average flow of 5,000 gpd with a solid raw influent and high O&G. The average Influent COD, BOD, TSS, NH3-N, were 570, 376, 109, and 53 mg/l, respectively. The influent organic load was unstable. It fluctuated 2-3 times higher than average influent strength in BOD, NH3-N, and O&G. Therefore, the plant was often upset, and sludge was washed out several times yearly in 2019. Since the SBR aeration device was rated at 25 HP (33.5KW) with an aerator, mixer, and decanter in one unit, it could not shut down the aeration during anoxic fill. Therefore, the energy consumption was high. The SBR system could not maintain the necessary biomass and DO control to accomplish nitrification/denitrification effectively and had difficulty facing unstable influent shock load.

An FMBR full-scale 5000 gpd pilot demonstration project was installed and has been running at the Plymouth Municipal Airport plant since November 2019. It has converted the full SBR flow to the FMBR system since inception and is now in the process of approval by the Massachusetts Department of Environmental Protection. The installed aeration device is a 2.2 KW diaphragm air compressor. The system started with seeded sludge from other FMBR systems that had acclimated to a low DO condition. The energy consumption was measured at about 44 kwh/d vs. the SBR consumption of 367 kwh/d. The overall energy and cost savings are about 77 % and 73%, respectively, compared to the existing SBR plant. Effluent BOD and TSS are under detectable limits (Table 1). TN is between 3-6 mg/l without adding external carbon.

Page 2 of 32

Effluent TP is less than 1.0 mg/l even though the plant permit doesn’t require phosphorus removal. In addition, it also saves 90% on chemical costs and 50% on sludge disposal costs compared to that of SBR’s 25,000 gal/year (refer to Figure 1)

The FMBR system is robust. The high MLSS concentration (12,00020,000 ppm) and a consortium of diverse nitrifiers and novel facultative ammonia-oxidizing organisms make the FMBR system more robust to loading changes. It can recover from upset quickly. The longer the system runs, the better the microorganisms acclimate to the facultative environment. The result shows that the FMBR system can tolerate influent organic shock loads much better than the SBR system.

FMBR started on November 22, 2019, with an 60oF cold temperature and the worst condition of high influent of BOD 470 mg/l, NH3-N 68.6 mg/l, and O&G of 158 mg/l, respectively. However, one week after start-up, TN reduced to < 5 mg/l and stayed at that level for the rest of the startup period (refer to Tables 2, 3, and 4 and Figures 2, 4, and 5). Although FMBR has been impacted by decayed sludge with high NH3-N settling in the SBR tank, the system can recover quickly in 2-3 days. The effluent TN is always under ten mg/l at shock load impact. After the FMBR equipment arrived at the PMA site, it only took 1.5 months to complete the installation and startup operation. It was 4.5 months ahead of the project schedule. FMBR can quickly be brought online to deal with an emergency, especially when a plant upgrade expansion is under construction.

Principle of FMBR

Cell decay is the principal mechanism of sludge reduction and the elimination of external carbon addition. Due to the high biomass concentration, long SRT, and low DO conditions, the diverse nitrifiers, novel ammonia-oxidizing organisms (including AOA, anammox), PAOs, and denitrifying PAOs can coexist in the same facultative environment and compete with each other to form a microbial food web and remove C, N and P simultaneously. The FMBR system is robust. The high MLSS concentration (12,000~20,000 ppm) and a consortium of diverse nitrifiers and novel facultative ammonia-oxidizing organisms make the FMBR system more robust to loading changes. It can recover from upset quickly. The longer the system runs, the better the microorganisms acclimate to the facultative environment.

FMBR has been installed in over 3000 projects in 19 countries for various client applications except the US. FMBR has won the IWA project innovation award in 2014 and recently won the 2018 R&D 100 Award as a special recognition corporation. It has been highly praised by URS, the authority on international standards, as having “the potential to be the ground-breaking & leading technology in the 21st century’s wastewater treatment industry”.

FMBR applications include domestic sewage, industrial wastewater, and brewery wastewater. The longer the FMBR operates, the better performance it achieves because microbial activities have been cultivated and acclimated in a low DO environment. The most important feature is the simple process control. Most small plants can operate unattended, and a mobile service station can take care of a plant’s routine maintenance.

Process: Activated Sludge, Moving Biomedia

Bioreactor (MBBR), Membrane

Bioreactor (MBR), Sequential Batch

Bioreactor (SBR)

Expensive sewer line collection system

Expensive to construct and maintain

COPYRIGHT © 2020. NEXTGEN SEPTICS. ALL RIGHTS RESERVED.